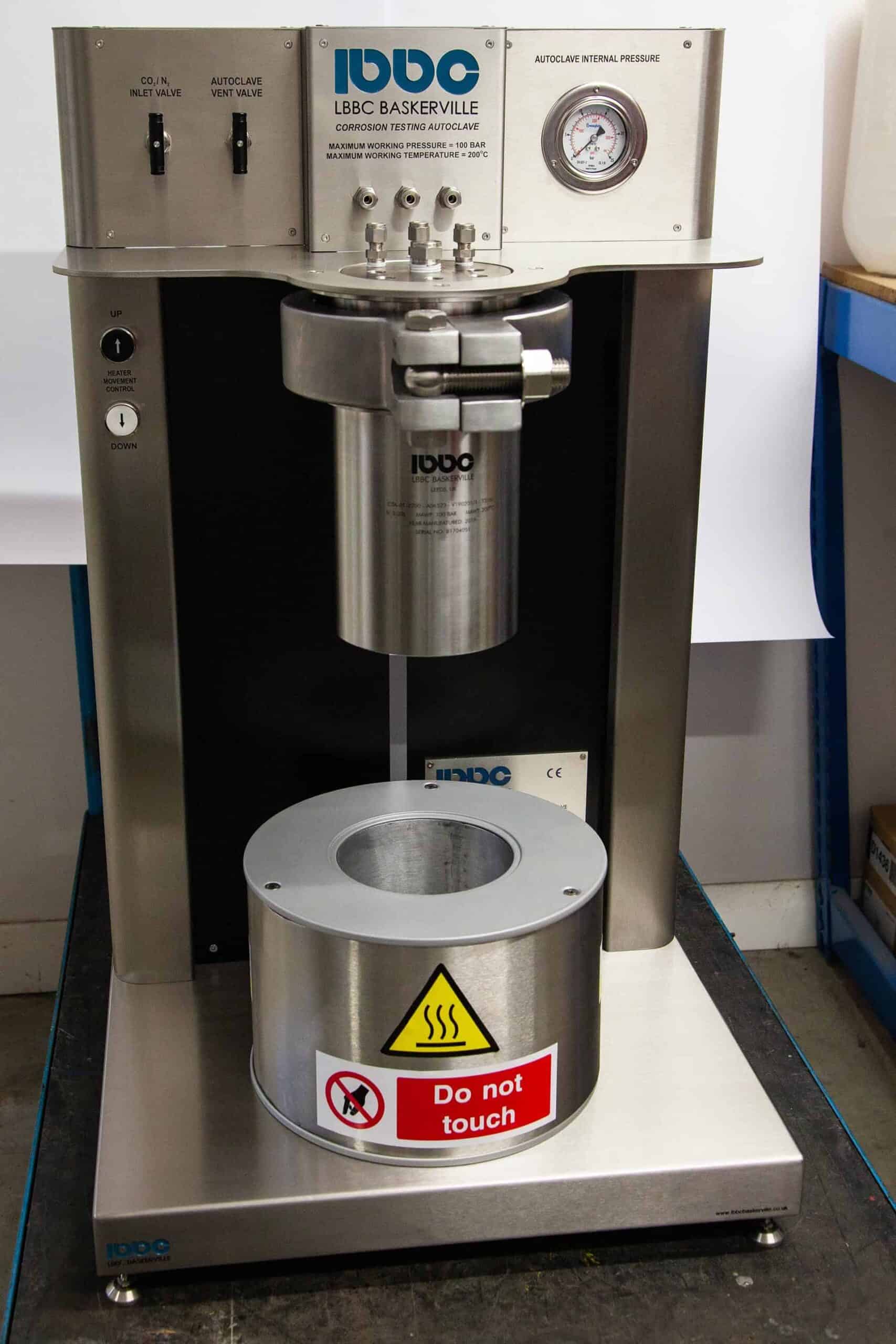

LBBC Baskerville’s corrosion testing autoclaves have been designed and manufactured, primarily for the oil and gas industry. The equipment can also be used in a number of other industries to simulate high pressure, high temperature (HPHT) environments such as nuclear, geothermal, carbon capture and storage, energy, defence, pharmaceutical and many more industries. The system has been designed to suit both industry and academic

The autoclave’s primary use is to evaluate material, coating or inhibitor performance, corrosion failure analysis in the form of weight loss coupons or electrochemical studies in aggressive high pressure (HP) and high temperature (HT) environments representative of the conditions found in the field throughout the oil and gas industry.